Automotive electronics are generally more expensive. One of the main reasons is the use of automotive-grade electronic components. But what kind of electronic components are automotive-grade devices? Let's take a look at the electronic components in the car. What is the difference between the application of this and general consumer electronics.

Temperature: Automotive electronics have relatively wide operating temperature requirements for components, and have different requirements based on different installation positions, but generally higher than the requirements of civilian products (It is said that AEC Q100 has deleted 0 ℃ -70 ℃ in the H version. Temperature requirements, because no car product requirements can be so low).

For example:

Engine periphery: -40 ℃ -150 ℃;

Passenger cabin: -40 ℃ -85 ℃;

Civilian products: 0 ℃ -70 ℃.

Other environmental requirements Humidity, mold, dust, water, EMC, and harmful gas erosion are often higher than consumer electronics requirements.

When a car works in a sports environment, many products will encounter more vibration and shock. This requirement may be much higher than products placed at home.

To illustrate the reliability requirements of the car, let me explain in another way:

1. Design life: The average design life of automobiles is about 15 years and 200,000 kilometers, which is much longer than the life requirements of consumer electronics.

2. Under the same reliability requirements, the more components and links the system has, the higher the reliability requirements for the components. At present, the electronic level of the car is very high. From the powertrain to the braking system, a large number of electronic devices are equipped, and each device is composed of many electronic components. If we simply think of them as a series relationship, then we must ensure that the entire vehicle achieves considerable reliability. The requirements for each part of the system composition are very high. This is why the requirements for automobile parts are often PPM (million 1)) to describe.

Today's cars have entered a stage of large-scale production. A car can produce hundreds of thousands of cars a year, so this requires very high product quality consistency. This was very challenging for semiconductor materials in the early years.

After all, the consistency of processes such as diffusion in the production of semiconductors is difficult to control. The performance of the products produced is easy to be scattered. In the early days, it could only be completed by aging and screening. The consistency of quality is also the biggest difference between many local suppliers and internationally renowned suppliers. For complex automotive products, it is definitely unacceptable that poorly consistent components cause safety hazards in the entire vehicle.

Let's look at some other requirements:

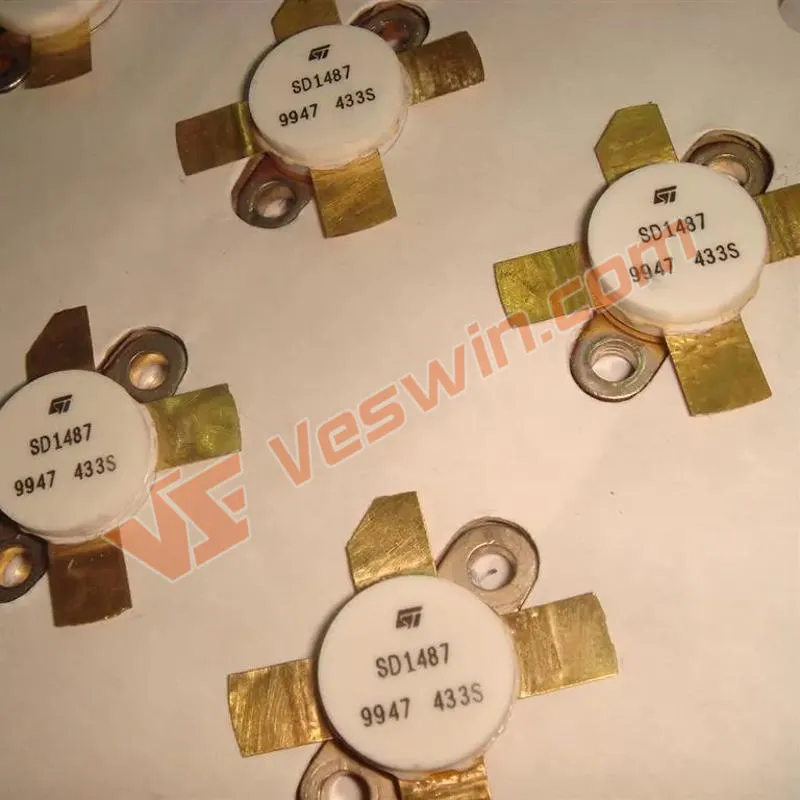

The requirements for the manufacturing process of automotive products, although automobile parts are also continuously developing towards miniaturization and light weight, but relative to consumer products, they can be relatively relaxed in terms of volume and power consumption. Generally, the packaging is larger to ensure It has sufficient mechanical strength and conforms to the manufacturing processes of major automotive suppliers.

Product Lifecycle

Although in recent years, automobile products have continued to reduce prices, automobiles are still a large, durable commodity that must maintain the ability to provide after-sales accessories for a long time. At the same time, the development of an automobile part requires a large amount of verification work, and the verification work brought by replacement of components is also huge. Therefore, vehicle manufacturers and component suppliers also need to maintain stable supply for a long time.

Standard

From this point of view, it is really complicated to meet the requirements of automotive products, and the above requirements are for automotive parts (for electronic components, it is a system). How to convert the requirements to electronic components becomes very difficult. In order to solve this problem, Naturally, there are some normative standards, and the more widely recognized is the AEC standard:

AEC Q100 Requirements for Active Device Components

AEC Q200 Requirements for Passive Device Components

Of course, I guess many people will also say that there are many enterprise standards for OEMs. But I also want to talk about my understanding. The OEMs I have worked in before do have relevant standards for general reliability requirements, but it evaluates a complete automotive component (a system of electronic components), not directly against the electronic components that make up these components Requirements (resistors, capacitors, transistors, chips, etc.), although its requirements can be used to refer to the selection of lower-level components, but it is still very inappropriate as an electronic component test.

Vehicle Regulation Verification

In my previous work, it is inevitable that some electronic components without AEC Q100 / 200 certification will be used, and many car manufacturers will want to perform some reliability verification to verify whether it meets vehicle regulations.

My personal opinion is that this method is not very effective, because these tests can only be necessary and insufficient tests. It can only be used to deny the availability of the device, not to be sure it can be used.

The reason is simple. The number of samples tested is not sufficient. For semiconductors such as mass-produced components, the reliability is determined by testing a small number of samples. Personally, it is very unreliable. Here we can also take a look at the main certification test items carried out by AEC Q100. You can see the difference.

Who has the highest requirements for car regulations and industrial regulations. The standard is generally considered to be military> automotive> industrial> consumer electronics. But individuals cannot fully accept this order. Industry is a very wide area, and the environmental and reliability needs also vary greatly. It can be imagined that, for example, the reliability requirements of a large-scale industrial equipment will never be lower than the requirements of automobiles. (Such as the key equipment of a large power plant). At the same time, the harsh environment of the environment may far exceed the requirements of the car. It cannot be simply said that the industrial regulations are lower than the car.

No choice can only be good without harm. What are the disadvantages of using car-specific electronic components?

The first is expensive, high system requirements, high development and verification costs, and low output lead to a cost that is much higher than consumer electronics. The relatively high threshold also results in a higher sales premium.

The second disadvantage is that the selection is difficult. Everyone who plays electronics knows that to this day, electronic components are quite abundant. There can be multiple solutions for products with the same function. The complexity may vary greatly, but sometimes in order to meet the requirements of car regulations, some high-integration Program.

Another obvious disadvantage is that some products are lagging behind in technology. A large amount of verification has affected the speed of new products to market. At the same time, the general launch strategy of chip manufacturers also hopes to apply the product to the consumer electronics market after it matures To the car market. For example, the ARM Cortex A9 processor used in a product developed by Xiaobian in 2013 was basically the best product in the automotive market, but the ARM Cortex A57 processor in the consumer market is not unusual.

This problem is really complicated, and it has to be judged from multiple aspects:

1. It just doesn't get the relevant certification, but the performance and reliability of the product meet the requirements, and it has also been verified by a large number of applications. If this is the case, the risk is relatively small.

2. This is an important point, which is the relationship between components and systems. The performance and reliability of the system are composed of the next-level electronic components, so under the same design, the use of non-vehicle-specific components must be inferior. However, a good design can reduce the performance requirements of the component. A well-designed protection measure and the design of the component failure will have a slight impact on the system. It is possible to use non-vehicle-specific components to make better products.

Due to the impact of current technological process limitations, not every electronic component that needs to be used in a car can meet the so-called car regulations. But in order to achieve some functions in the car, these components must be used. This situation can be divided into two categories:

a. This function has high safety requirements and cannot accept deviation

Example: E-CALL function for emergency call. To ensure this function, a backup battery must be installed on the device. This function is related to life safety. According to the ASILI (ISO26262) rating of some companies, it is required to reach B level.

We know that it is difficult to maintain high performance for batteries at -40 degrees. Therefore, the solution of some companies is to heat the resistance wire on the battery and heat it at low temperature to ensure the performance. At this time, the standard of a single component is unqualified, but as a component assembly, it can meet the standard requirements of the car manufacturer . This also shows the relationship between the OEM's corporate standards and component standards.

b. This function generally does not involve safety, and can consider accepting deviations

Such as the LCD screen of the entertainment system. At low temperatures, the response and optical performance may be degraded. But this situation will be accepted by some engineering staff.

3. Some "bold" people who are not careful, for some ideas, such as reducing costs, or can obtain better performance, and only want to verify their performance and Reliability. In this case, I can only say that future things depend on character. No one knows what will happen.

Hot News