SMD (Surface Mount Device), it is a kind of SMT (Surface Mount Technology) electronic components. In addition, SMD components for SMT do not have leads like through-hole components, and in terms of electrical functions, SMD components for SMT are no different from through-hole components, but SMD is smaller in size and thus has better electrical functions .

Currently, not all components are available for surface mount in electronic PCB assembly, therefore, full surface mount on PCB is not available and is currently basically limited to mix and match surface mount components. The use of through-hole components such as BGAs and pin grid arrays (PGAs) in high-end processors and large connectors will keep the industry in a mixed assembly model for the foreseeable future.

While there are only a few types of traditional DIP packages that can meet all packaging requirements, the technology for surface mount packages is much more complex.

There are many package types and package and lead configurations available. In addition, the requirements for surface mount components are much higher. SMD or SMC must withstand higher soldering temperatures and must be selected, placed and soldered more carefully to achieve acceptable manufacturing yields.

There are many components available for certain electrical requirements, leading to weight issues with component proliferation.

In addition, some electronic components are sold at discounted prices while others are sold at a premium. While surface mount technology is mature, it is also evolving as new packages are introduced. The electronics industry is grappling with the economics, technology and standardization of surface mount components every day. At the same time, SMDs can also be used as active and passive electronic components.

The technology of passive surface mount is slightly simpler, including monolithic ceramic capacitors, giant capacitors and thick film capacitors, which form the core group of passive SMD. The shape is generally rectangular and cylindrical, and the mass of the component is about 10 times lower than that of the through-hole counterpart.

Surface mount capacitors and capacitors are available in a variety of case sizes to meet the needs of various applications in the electronics industry. While there is a trend towards smaller case sizes, larger case sizes can also be used if capacitance requirements are significant. These devices/assemblies are available in rectangular and tubular (lead-free side of metal electrodes) shapes.

There are two main types of surface mount resistors(SMD Resistor): thick film and thin film.

Thick film surface mount electrodes are constructed by screening an electrode film (Nail Dioxide-based paste or similar material) on a flat high-purity alumina substrate surface, which is the same as a circular electrode in an axial electrode. The electropositive film deposited on the core is different.The electropositive value is obtained by changing the composition of the electropositive slurry before screening and laser trimming the film after screening.

In thin film electrodes, the electrode element on a ceramic substrate has a protective coating on top (glass passivation) and solderable terminals (tin-lead) on the sides. Terminals have an adhesion layer « silver deposited as a thick film paste » on a ceramic substrate, and a nickel anode spacer layer, followed by a solder dip or electroplated solder coating. The nickel anode barrier is very important to maintain the solderability of the terminals because it prevents the leaching (dissolution) of the silver or gold electrodes during SMD soldering.

Electrodes are available in 1/16, 1/10, 18, and 1/80,000 ratings, and are available in 1 ohm to 100 ohms in various sizes and with various tolerances. Common sizes are: 0402, 0603, 0805, 1206 and 1210. Surface mount electrodes have some form of colored electrode layer with a protective coating on one side and usually a self-colored substrate on the other. Therefore, it provides an easy way to distinguish between electro anodes and capacitors from the appearance.

Surface mount resistor networks (R-pack) are often used as a replacement for discrete resistor series. Currently available styles are based on the popular SOIC (Small Outline Integrated Circuit), but vary in body size. They usually have 16 to 20 pins and draw 1/2 to 2 watts per package.

Surface mount capacitors are ideal for high frequency circuit applications as they do not have any leads and can be placed under the package on the other side of the PCB assembly. The most widely used package for ceramic capacitors is 8 mm tape and reel.

Surface mount capacitors are used for decoupling applications and frequency control. Multilayer monolithic ceramic capacitors improve volumetric efficiency. They are available in different dielectric types, COG or NPO, X7R, Z5U and Y5V according to the EIA RS-198n standard.

Surface mount capacitors are very reliable and are used in large numbers under the hood of automobiles, military equipment, and aerospace applications.

For surface mount capacitors, the dielectric can be ceramic or aluminum. Surface Mount Aluminum Capacitors offer very high volumetric efficiency or high capacitance voltage product per unit volume and high reliability.

Wrapped-lead capacitors, often called plastic molded capacitors, have leads instead of terminals and a beveled top as a polarity indicator. There are no soldering or placement issues when using molded plastic jumbo capacitors. They are available in two housing sizes - standard and extended range.

Tantalum capacitors vary in capacitance value from 0.1 to 100 uF, from 4 to 50 V dc in different case sizes, and they can also be customized according to the requirements of the application. Jumbo capacitors are available with or without marked capacitance values, in bulk, box, and tape and reel packaging.

Cylindrical devices called Metal Electrode Leadless Faces (MELF) are used in capacitors, jumpers, ceramic and giant capacitors, and diodes. They are cylindrical and have metal end caps for welding.

Because the MELF is cylindrical, the resistor does not have to be placed on the resistor component away from the board surface like a rectangular resistor. MELF is cheaper. Like traditional axial units, the MELF has color-coded values. MELF diodes are identified as MLL41 and MLL34. MELF electrophoresis identifications are 0805, 1206, 1406 and 2309.

Surface mount offers more types of active and passive packages than through-hole technology. Below are all the different categories of active surface mount component packages.

Leadless Ceramic Chip Carrier (LCCC), as the name suggests, is a leadless chip carrier without leads. Instead, they have gold-plated slot terminals, called castellations, that provide a shorter signal path, allowing for higher operating frequencies. LCCC can be divided into different series according to the pitch of the package. The most common is the 50mil (1.27 mm) series. Others are 40, 25 and 20mil series.

Ceramic Leaded Chip Carriers (CLCC) (pre-leaded and post-leaded); leaded ceramic carriers are available in pre-leaded and post-leaded forms. Pre-leaded chip carriers have copper alloy or Kovar leads attached by the manufacturer. In post-lead chip carriers, the user attaches the leads to the lead-free ceramic chip carrier's intermediary structure. When leaded ceramic packages are used, they are usually the same size as plastic leaded chip carriers.

Active SMT components (plastic package); mainly used in military applications due to the high cost of ceramic packages. Plastic SMD packages, on the other hand, are the most widely used packages in non-military applications and do not require hermeticity. Ceramic packages suffer from solder joint cracking due to CTE mismatch between package and substrate, but plastic packages are not without problems.

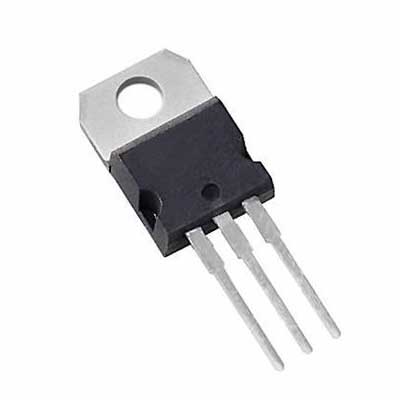

Small Outline Transistor (SOT); Small Outline Transistors are one of the forerunners of surface mount active devices, and they are three- and four-lead devices. Three-lead SOTs are identified as SOT 23 (EIA TO 236) and SOT 89 (EIA TO 243). The four-lead device is called SOT 143 (EIA TO 253). These packages are commonly used for diodes and transistors. SOT 23 and SOT 89 packages have become almost universal surface mount small transistors. Even as the use of high pin-count complex integrated circuits becomes more common, the demand for winter types of SOTs and SODs continues to grow.

Small Outline Integrated Circuit (SOIC and SOP); Small Outline Integrated Circuit (SOIC or SO) is basically a shrink package with leads 0.050 inches on center, which is used to accommodate larger integrated circuits than SOT packages. In some cases, SOICs are used to accommodate multiple SOTs. SOIC contains leads formed on both sides, often called chicken wing leads. SOIC requires careful handling to prevent lead damage. SOIC mainly comes in two different body widths: 150mi and 300ml. Packages with fewer than 16 leads have a body width of 150mil; for more than 16 leads, use a 300mil width. The 16-pin package is available in two body widths.

Plastic Leaded Chip Carrier (PLCC), Plastic Wire Chip Carrier PLCC) is a cheaper version of the ceramic chip carrier. The leads in the PLCC provide the compliance needed to withstand the stress of the solder joint, thus preventing cracking of the solder joint. Note that PLCC with a large chip-to-package ratio may cause package cracking due to moisture absorption.

Small Outline J Package (SOJ); SOJ packages have J-bend leads similar to PLCCs, but they only have leads on both sides. The package is a hybrid of SOIC and PLCC, combining the processing advantages of PLCC with the space efficiency of SOIC. SOJ is commonly used for high density (1, 4 and 16 MB) DRAMS.

Fine-pitch SMD packages (OFP, SOFP); SMD packages with very fine pitches and a large number of pins are called fine-pitch packages. Quad Flat Pack (OFP) and Shrink Quad Flat Pack (SOFP) are examples of fine-pitch packages. Fine-pitch packages have thinner leads and require thinner land pattern designs.

Ball Grid Array (BGA) SMD components, BGA or Ball Grid Array is an array package similar to PGA (Pin Grid Array), but without leads. There are currently many types of BGAs, but the main categories are ceramic and plastic BGAs.

Ceramic BGA is called CBGA (Ceramic Ball Grid Array) and CCGA (Ceramic ColumnGrid Array), and plastic BGA is called PBGA. There is another type of BGA called tape BGA (TBGA). Ball pitches have been standardized to 1.0, 1.27 and 1.5mm pitches.

BGA body sizes range from 7 to 50 mm, and their pin counts range from 16 to 2400. The most common BGA pin counts are between 200 and 500 pins. That makes the BGA misaligned by 50% (CCGA and TBGA don't self-align like PBGA and CBGA), BGA is also very good at self-aligning during reflow, which is one of the reasons why BGA yield is higher.

Hot News